گرافيت

ساهم بشكل رئيسي في تحرير هذا المقال

|

| الگرافيت Graphite | |

|---|---|

عينة گرافيت | |

| العامة | |

| التصنيف | معدن عنصري أصلي |

| الصيغة (repeating unit) | كربون |

| تصنيف سترونز | 01.CB.05a |

| النظام البلوري | Hexagonal |

| Space group | Hexagonal dihexagonal dipyramidal H-M symbol: (6/m 2/m 2/m) Space group: P 63/mmc |

| Unit cell | a = 2.461 Å, c = 6.708 Å; Z = 4 |

| التعرف | |

| Color | Iron-black to steel-gray; deep blue in transmitted light |

| Crystal habit | Tabular, six-sided foliated masses, granular to compacted masses |

| Twinning | Present |

| Cleavage | Basal - perfect on {0001} |

| Fracture | Flaky, otherwise rough when not on cleavage |

| Tenacity | Flexible non-elastic, sectile |

| Mohs scale hardness | 1–2 |

| Luster | لامع، ترابي |

| Streak | أسود |

| Diaphaneity | Opaque, transparent only in extremely thin flakes |

| الكثافة | 2.09–2.23 g/cm3 |

| الصفات البصرية | Uniaxial (–) |

| Pleochroism | Strong |

| قابلية الذوبان | Molten Ni |

| References | [1][2][3] |

الگرافيت أحد أشكال الكربون المتآصلة. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on large scale (300 kton/year, in 1989) for uses in pencils, lubricants, and electrodes. Under high pressures and temperatures it converts to diamond. It is a good (but not excellent) conductor of both heat[4] and electricity.[5] وبعكس الألماس، فالجرافيت موصل للكهرباء ويمكن استخدامه، على سبيل المثال، في أقطاب الأقواس الكهربائية.

الأنواع والتنويعات

الجرافيت الطبيعي

The principal types of natural graphite, each occurring in different types of ore deposits, are

- Crystalline small flakes of graphite (or flake graphite) occurs as isolated, flat, plate-like particles with hexagonal edges if unbroken. When broken the edges can be irregular or angular;

- Amorphous graphite: very fine flake graphite is sometimes called amorphous;[6]

- Lump graphite (or vein graphite) occurs in fissure veins or fractures and appears as massive platy intergrowths of fibrous or acicular crystalline aggregates, and is probably hydrothermal in origin.[7]

- Highly ordered pyrolytic graphite refers to graphite with an angular spread between the graphite sheets of less than 1°.[8]

- The name "graphite fiber" is sometimes used to refer to carbon fibers or carbon fiber-reinforced polymer.

الجرافيت الاصطناعي

Synthetic graphite is a material consisting of graphitic carbon which has been obtained by graphitizing of non-graphitic carbon, by CVD (chemical vapor deposition) from hydrocarbons at temperatures above 2500 K, by decomposition of thermally unstable carbides or by crystallizing from metal melts supersaturated with carbon.[9]

تواجد الجرافيت الطبيعي

Graphite occurs in metamorphic rocks as a result of the reduction of sedimentary carbon compounds during metamorphism. It also occurs in igneous rocks and in meteorites.[3] Minerals associated with graphite include quartz, calcite, micas and tourmaline. The principal export sources of mined graphite are in order of tonnage: China, Mexico, Canada, Brazil, and Madagascar.[10]

In meteorites, graphite occurs with troilite and silicate minerals.[3] Small graphitic crystals in meteoritic iron are called cliftonite.[7] Some microscopic grains have distinctive isotopic compositions, indicating that they were formed before the Solar System.[11] They are one of about 12 known types of minerals that predate the Solar System and have also been detected in molecular clouds. These minerals were formed in the ejecta when supernovae exploded or low to intermediate-sized stars expelled their outer envelopes late in their lives. Graphite may be the second or third oldest mineral in the Universe.[12][13]

ينتشر خام الجرافيت الطبيعي على نطاق واسع في جميع أنحاء العالم. والدول الرئيسية المنتجة للجرافيت الطبيعي وفقًا لترتيب الأهمية هي: الصين وكوريا الجنوبية والمكسيك والنمسا. ويمكن تصنيع الجرافيت من فحم الكوك بتسخينه في أفران كهربائية. وقد طوَّر المخترع الأمريكي إدوارد أشيسون عملية صناعة الجرافيت من فحم الكوك سنة 1896م. والجرافيت الصناعي أكثر نقاء وأكثر كثافة من الجرافيت الطبيعي. وهو كذلك أكثر تكلفة.

وللجرافيت استخدامات متعددة بالإضافة إلى استخدامه في أقلام الرصاص. فهو موصل للكهرباء، ومن الصعب أن يحترق. ولهذه الأسباب تصنع الأقطاب الكهربائية (نقاط الاتصال الكهربائي) من الجرافيت الذي يعمل تحت ظروف تُدمِّر الأقطاب الفلزية. والجرافيت موصل للحرارة، ولا يتحد بأية عناصر كيميائية أخرى، إلا في درجات حرارة عالية جدًا. وعلى هذا، فكثير من الجفان (أوعية صهر الفلزات) تُصنع من الجرافيت. والجرافيت لا يذوب بسهولة، ولهذا تُصنع منه الخزانات التي تحفظ بها الحموض القوية، كما أنه يستخدم في قلب بعض المفاعلات النووية. ويعمل الجرافيت على تهدئة سرعة النيوترونات في المفاعلات للمحافظة على عملها الدقيق. وانزلاقية الجرافيت تجعله مادة تشحيم جيدة لساعات الحائط، وأقفال الأبواب، والآلات الأخرى ذات الأجزاء الصغيرة. والجرافيت أيضًا هو المادة الخام الرئيسية في الماس الاصطناعي.

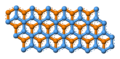

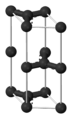

يصنع كل من الجرافيت والماس من الكربون النقي، ولكن الماس صلب للغاية وشفاف. والماس أكثر كثافة من كمية مساوية من الجرافيت. ويحتوي الجرافيت والماس على بناء بلّوري مختلف. ذلك أن ذرات الكربون منظمة بطريقة مختلفة في كل من المعدنين. فالجرافيت يحتوي على ذرات الكربون منتظمة في طبقات مسطحة، وهي تنزلق بسهولة بعضها فوق بعض. ولهذا فالجرافيت ناعم وزلق. أما الماس فذراته منتظمة في نمط ثلاثي الأبعاد، تمنع الذرات من انزلاق بعضها فوق بعض.

البنية

Graphite consists of sheets of trigonal planar carbon.[14][15] The individual layers are called graphene. In each layer, the carbon atoms are arranged in a honeycomb lattice with a bond length of 0.142 nm, and the distance between planes is 0.335 nm.[16] Bonding between layers is relatively weak van der Waals bonds and are often occupied by gases, which allows the graphene-like layers to be easily separated and to glide past each other.[17]

Electrical conductivity perpendicular to the layers is consequently about 1000 times lower.[18]

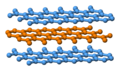

The two forms of graphite are called alpha (hexagonal) and beta (rhombohedral). Their properties are very similar. They differ in terms of the stacking of the graphene layers: stacking in alpha graphite is ABA, as opposed to ABC stacking in energetically less stable and less common beta graphite.[19] The alpha form can be converted to the beta form through mechanical treatment and the beta form reverts to the alpha form when it is heated above 1300 °C.[20]

Scanning tunneling microscope image of graphite surface

Alpha graphite's unit cell

الثرموديناميكا

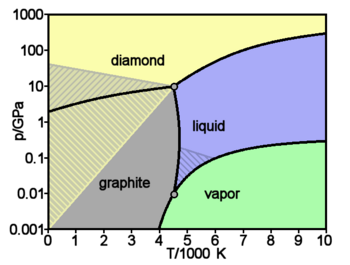

The equilibrium pressure and temperature conditions for a transition between graphite and diamond is well established theoretically and experimentally. The pressure changes linearly between 1.7 GPa at 0 K and 12 GPa at 5000 K (the diamond/graphite/liquid triple point).[21][22] However, the phases have a wide region about this line where they can coexist. At normal temperature and pressure, 20 °C (293 K) and 1 standard atmosphere (0.10 MPa), the stable phase of carbon is graphite, but diamond is metastable and its rate of conversion to graphite is negligible.[23] However, at temperatures above about 4500 K, diamond rapidly converts to graphite. Rapid conversion of graphite to diamond requires pressures well above the equilibrium line: at 2000 K, a pressure of 35 GPa is needed.[21]

الخصائص الأخرى

The acoustic and thermal properties of graphite are highly anisotropic, since phonons propagate quickly along the tightly bound planes, but are slower to travel from one plane to another. Graphite's high thermal stability and electrical and thermal conductivity facilitate its widespread use as electrodes and refractories in high temperature material processing applications. However, in oxygen-containing atmospheres graphite readily oxidizes to form carbon dioxide at temperatures of 700 °C and above.[24]

Graphite is an electrical conductor, hence useful in such applications as arc lamp electrodes. It can conduct electricity due to the vast electron delocalization within the carbon layers (a phenomenon called aromaticity). These valence electrons are free to move, so are able to conduct electricity. However, the electricity is primarily conducted within the plane of the layers. The conductive properties of powdered graphite[25] allow its use as pressure sensor in carbon microphones.

Graphite and graphite powder are valued in industrial applications for their self-lubricating and dry lubricating properties. There is a common belief that graphite's lubricating properties are solely due to the loose interlamellar coupling between sheets in the structure.[26] However, it has been shown that in a vacuum environment (such as in technologies for use in space), graphite degrades as a lubricant, due to the hypoxic conditions.[27] This observation led to the hypothesis that the lubrication is due to the presence of fluids between the layers, such as air and water, which are naturally adsorbed from the environment. This hypothesis has been refuted by studies showing that air and water are not absorbed.[28] Recent studies suggest that an effect called superlubricity can also account for graphite's lubricating properties. The use of graphite is limited by its tendency to facilitate pitting corrosion in some stainless steel,[29][30] and to promote galvanic corrosion between dissimilar metals (due to its electrical conductivity). It is also corrosive to aluminium in the presence of moisture. For this reason, the US Air Force banned its use as a lubricant in aluminium aircraft,[31] and discouraged its use in aluminium-containing automatic weapons.[32] Even graphite pencil marks on aluminium parts may facilitate corrosion.[33] Another high-temperature lubricant, hexagonal boron nitride, has the same molecular structure as graphite. It is sometimes called white graphite, due to its similar properties.

When a large number of crystallographic defects bind these planes together, graphite loses its lubrication properties and becomes what is known as pyrolytic graphite. It is also highly anisotropic, and diamagnetic, thus it will float in mid-air above a strong magnet. If it is made in a fluidized bed at 1000–1300 °C then it is isotropic turbostratic, and is used in blood-contacting devices like mechanical heart valves and is called pyrolytic carbon, and is not diamagnetic. Pyrolytic graphite and pyrolytic carbon are often confused but are very different materials.[34]

Natural and crystalline graphites are not often used in pure form as structural materials, due to their shear-planes, brittleness, and inconsistent mechanical properties.

تاريخ استخدام الجرافيت الطبيعي

يستخدم الصناعيون الجرافيت في كثير من المنتجات. وعلى سبيل المثال يقومون بتقويته بالصلصال، لإنتاج مادة أقلام الرصاص التي نسميها رصاصًا. وفي وقت ما كان الناس يطلقون على الجرافيت خطأ اسم الرصاص، ولكن الرصاص أكثر كثافة من الجرافيت. والاسم جرافيت مشتق من كلمة يونانية معناها يكتب. وقد أُطلق الجيولوجي الألماني أبراهام فيرنر هذا الاسم عليه سنة 1789م.

In the 4th millennium BCE, during the Neolithic Age in southeastern Europe, the Marița culture used graphite in a ceramic paint for decorating pottery.[35]

Sometime before 1565 (some sources say as early as 1500), an enormous deposit of graphite was discovered on the approach to Grey Knotts from the hamlet of Seathwaite in Borrowdale parish, Cumbria, England, which the locals found useful for marking sheep.[36][37] During the reign of Elizabeth I (1558–1603), Borrowdale graphite was used as a refractory material to line molds for cannonballs, resulting in rounder, smoother balls that could be fired farther, contributing to the strength of the English navy. This particular deposit of graphite was extremely pure and soft, and could easily be cut into sticks. Because of its military importance, this unique mine and its production were strictly controlled by the Crown.[38]

During the 19th century, graphite's uses greatly expanded to include stove polish, lubricants, paints, crucibles, foundry facings, and pencils, a major factor in the expansion of educational tools during the first great rise of education for the masses. The British Empire controlled most of the world's production (especially from Ceylon), but production from Austrian, German, and American deposits expanded by mid-century. For example, the Dixon Crucible Company of Jersey City, New Jersey, founded by Joseph Dixon and partner Orestes Cleveland in 1845, opened mines in the Lake Ticonderoga district of New York, built a processing plant there, and a factory to manufacture pencils, crucibles and other products in New Jersey, described in the Engineering & Mining Journal 21 December 1878. The Dixon pencil is still in production.[39]

The beginnings of the revolutionary froth flotation process are associated with graphite mining. Included in the E&MJ article on the Dixon Crucible Company is a sketch of the "floating tanks" used in the age-old process of extracting graphite. Because graphite is so light, the mix of graphite and waste was sent through a final series of water tanks where a cleaner graphite "floated" off, which left waste to drop out. In an 1877 patent, the two brothers Bessel (Adolph and August) of Dresden, Germany, took this "floating" process a step further and added a small amount of oil to the tanks and boiled the mix – an agitation or frothing step – to collect the graphite, the first steps toward the future flotation process. Adolph Bessel received the Wohler Medal for the patented process that upgraded the recovery of graphite to 90% from the German deposit. In 1977, the German Society of Mining Engineers and Metallurgists organized a special symposium dedicated to their discovery and, thus, the 100th anniversary of flotation.[40]

In the United States, in 1885, Hezekiah Bradford of Philadelphia patented a similar process, but it is uncertain if his process was used successfully in the nearby graphite deposits of Chester County, Pennsylvania, a major producer by the 1890s. The Bessel process was limited in use, primarily because of the abundant cleaner deposits found around the globe, which needed not much more than hand-sorting to gather the pure graphite. The state of the art, ca. 1900, is described in the Canadian Department of Mines report on graphite mines and mining when Canadian deposits began to become important producers of graphite.[40][41]

أسماء أخرى

Historically, graphite was called black lead or plumbago.[7][42] Plumbago was commonly used in its massive mineral form. Both of these names arise from confusion with the similar-appearing lead ores, particularly galena. The Latin word for lead, plumbum, gave its name to the English term for this grey metallic-sheened mineral and even to the leadworts or plumbagos, plants with flowers that resemble this colour.

The term black lead usually refers to a powdered or processed graphite, matte black in color.

Abraham Gottlob Werner coined the name graphite ("writing stone") in 1789. He attempted to clear up the confusion between molybdena, plumbago and black lead after Carl Wilhelm Scheele in 1778 proved that there are at least three different minerals. Scheele's analysis showed that the chemical compounds molybdenum sulfide (molybdenite), lead(II) sulfide (galena) and graphite were three different soft black minerals.[43][44][45]

الخصائص

التشكيل

صورة بالمجهر الماسح النفقي لذرات سطح الجرافيت. خلية الوحدة للجرافيت. نموذج الكرة والعصا للجرافيت (2 طبقة جرافيت)

استخدامات الجرافيت الطبيعي

Natural graphite is mostly used for refractories, batteries, steelmaking, expanded graphite, brake linings, foundry facings, and lubricants.[46]

الحراريات

تستخدم صور مختلفة من الكربون بشكل متزايد في الحراريات. فعلى سبيل المثال، الحراريات الحديثة تَستخدِم صور جرافيت مختلفة في توليفة مع أكاسيد أخرى لمنح الحراريات خصائص خاصة. وقد يكون الجرافيت ذو طبيعة اصطناعية حيث يُنتج بتسخين كوك البترول المكلس إلى 3000 ْم أو قد يكون طبيعياً حيث يستخرج من الصين والمكسيك وكندا، إلخ. ويمكن أن تُنْتَج بعض الحراريات من الكربون الخالص أو الجرافيت الخالص للاستخدام في تطبيقات الأجواء شديدة الاختزال.[47]

وعموما، يستخدم الجرافيت في الحراريات من أجل الحد من الخصائص التَبَلْلُّيَّة للمواد الحرارية التى تؤثر بشكل مباشر في التآكل الناتج عن الخبث، ولرفع الموصلية الحرارية التى ستؤدى إلى تحسين مقاومة الصدمات الحرارية. في الحراريات المبنية على أكسيد-كربون، قد يتغير محتوى الكربون من محتوى منخفض مثل 4-5 ٪ وقد يصل إلى 30-35 ٪. كما نلاحظ أنه بزيادة المحتوى الجرافيتى تزداد الموصلية الحرارية للحراريات، ولكن تقل كثافتها في الوقت ذاته. هذه النتيجة ترجع أساساً إلى حقيقة أن كثافة الجرافيت أقل بكثير من كثافة المواد الحرارية الأخرى المستخدمة. وهناك اختلافات أخرى واضحة في شكل (مورفولوجية) الجرافيت بالمقارنة مع غيره من المواد الحرارية، فمواد الجرافيت التى تستخدم في الحراريات عادة ما تكون ذات بنية قُشَارِيَّة (أى تتكون من قُشيرات)، ومن ثم فإن هذه القشيرات لا تستسلم لظواهر تعبئة الجسيمات كما تفعل الجسيمات الحبيبية.

يبين جدول 17 خصائص عدة أنواع من الجرافيت. يُنَقَّى الجرافيت القُشيرى عادة إلى محتويات عالية للغاية من الكربون: 99 ٪ بالوزن كربون أو أعلى، وتستعمل هذه التنقية عملية كيميائية وأخرى حرارية؛ ولهذه الخطوات تأثير كبير على سعر المواد.

مقاومة الصهر

هذا الاستعمال النهائي بدأ قبل سنة 1900 باستخدام بوتقة من الگرافيت للإمساك بالفلز المنصهر; وهو الآن جزء صغير من المصاهر. وفي منتصف عقد 1980، ازدادت أهمية طوب الكربون-مغنسيت، وبعد ذلك بقليل شكل الألومينا-گرافيت. ترتيب الأهمية حاليًا هو أشكال الألومينا والجرافيت، والطوب الكربوني والمجنسيت، والمواد المتجانسة (خليط إطلاق النار والصدم)، ثم البوتقات. بدأت البوتقات باستخدام رقائق الجرافيت الكبيرة جدًا، وطوب المجنسيت الكربوني الذي لا يتطلب شرائح جرافيت كبيرة الحجم؛ بالنسبة لهذه وغيرها، هناك الآن مرونة أكبر بكثير في حجم الرقائق المطلوبة، ولم يعد الجرافيت غير المتبلور يقتصر على الحراريات المنخفضة. تُستخدم أشكال الألومينا-الجرافيت كأدوات صب مستمرة، مثل الفوهات والأحواض، لنقل الفولاذ المنصهر من المغرفة إلى القالب، كما يستخدم طوب المجنسيت الكربوني في خط محولات الصلب وأفران القوس الكهربائي لتحمل درجات الحرارة القصوى. تُستخدم كتل الجرافيت أيضًا في أجزاء من بطانات الأفران اللافحة حيث تكون الموصلية الحرارية العالية للجرافيت أمرًا بالغ الأهمية. غالبًا ما تستخدم المواد المتجانسة عالية النقاء كبطانة مستمرة للفرن بدلاً من الطوب المغنسيوم الكربوني. واجهت صناعة الحراريات الأمريكية والأوروبية أزمة في الفترة 2000-2003، مع سوق غير مبال للصلب وانخفاض استهلاك الحراريات لكل طن من الصلب الأساسي لعمليات شراء الشركات وإغلاق العديد من المصانع. العديد من عمليات إغلاق المصانع نتجت عن استحواذ شركة RHI على حراريات هاربيسون-واكر؛ بيعت معدات بعض المصانع بالمزاد العلني. نظرًا لأن الكثير من السعة المفقودة كانت من طوب المغنسيوم الكربوني، فقد انتقل استهلاك الجرافيت داخل منطقة الحراريات نحو أشكال الألومينا-الجرافيت والمتجانسات، وبعيدًا عن الطوب. المصدر الرئيسي لطوب الكربون-مغنسيت هو الصين. تُستخدم جميع الحراريات المذكورة أعلاه تقريبًا في صناعة الصلب وتمثل 75% من استهلاك الحراريات؛ ويستخدم الباقي في مجموعة متنوعة من الصناعات، مثل الأسمنت. بحسب المسح الجيولوجي الأمريكي، عام 2006 بلغ استهلاك الولايات المتحدة من الجرافيت الطبيعي في الحراريات 11.000 طن و11.800 طن عام 2005.

صناعة الصلب

يستخدم الجرافيت الطبيعي في هذا الاستخدام النهائي غالباً في رفع الكربون في الصلب المصهور، على الرغم من أنه يمكن استخدامه لتليين القوالب المستخدمة في بثق الصلب الساخن. يعد توريد معزز الكربون أمرًا تنافسيًا للغاية، وبالتالي يخضع لتسعير حاد من البدائل مثل مسحوق الجرافيت الاصطناعي وفحم الكوك وأشكال الكربون الأخرى. تتم إضافة رافع الكربون لزيادة محتوى الكربون في الصلب إلى المستوى المحدد. يشير تقدير استهلاك GAN استنادًا إلى إحصائيات استهلاك الجرافيت الأمريكية الصادرة عن المسح الجيولوجي الأمريكي إلى أنه تم استخدام 10.500 طن بهذه الطريقة عام 2005.

كساء المكابح

Natural amorphous and fine flake graphite are used in brake linings or brake shoes for heavier (nonautomotive) vehicles, and became important with the need to substitute for asbestos. This use has been important for quite some time, but nonasbestos organic (NAO) compositions are beginning to reduce graphite's market share. A brake-lining industry shake-out with some plant closures has not been beneficial, nor has an indifferent automotive market. According to the USGS, US natural graphite consumption in brake linings was 6,510 tonnes in 2005.[46]

Foundry facings and lubricants

A foundry-facing mold wash is a water-based paint of amorphous or fine flake graphite. Painting the inside of a mold with it and letting it dry leaves a fine graphite coat that will ease the separation of the object cast after the hot metal has cooled. Graphite lubricants are specialty items for use at very high or very low temperatures, as forging die lubricant, an antiseize agent, a gear lubricant for mining machinery, and to lubricate locks. Having low-grit graphite, or even better, no-grit graphite (ultra high purity), is highly desirable. It can be used as a dry powder, in water or oil, or as colloidal graphite (a permanent suspension in a liquid). An estimate based on USGS graphite consumption statistics indicates that 2,200 tonnes were used in this fashion in 2005.[46] Metal can also be impregnated into graphite to create a self-lubricating alloy for application in extreme conditions, such as bearings for machines exposed to high or low temperatures.[48]

Everyday use

Pencils

The ability to leave marks on paper and other objects gave graphite its name, given in 1789 by German mineralogist Abraham Gottlob Werner. It stems from γράφειν ("graphein"), meaning to write or draw in Ancient Greek.[7][49]

From the 16th century, all pencils were made with leads of English natural graphite, but modern pencil lead is most commonly a mix of powdered graphite and clay; it was invented by Nicolas-Jacques Conté in 1795.[50][51] It is chemically unrelated to the metal lead, whose ores had a similar appearance, hence the continuation of the name. Plumbago is another older term for natural graphite used for drawing, typically as a lump of the mineral without a wood casing. The term plumbago drawing is normally restricted to 17th and 18th-century works, mostly portraits.

Today, pencils are still a small but significant market for natural graphite. Around 7% of the 1.1 million tonnes produced in 2011 was used to make pencils.[52] Low-quality amorphous graphite is used and sourced mainly from China.[46]

In art, graphite is typically used to create detailed and precise drawings, as it allows for a wide range of values (light to dark) to be achieved. It can also be used to create softer, more subtle lines and shading. Graphite is popular among artists because it is easy to control, easy to erase, and produces a clean, professional look. It is also relatively inexpensive and widely available. Many artists use graphite in conjunction with other media, such as charcoal or ink, to create a range of effects and textures in their work.[53]

هوايات

Pinewood derby

Graphite is probably the most used lubricant in pinewood derbies.[54]

Other uses

Natural graphite has found uses in zinc-carbon batteries, electric motor brushes, and various specialized applications. Graphite of various hardness or softness results in different qualities and tones when used as an artistic medium.[55] Railroads would often mix powdered graphite with waste oil or linseed oil to create a heat-resistant protective coating for the exposed portions of a steam locomotive's boiler, such as the smokebox or lower part of the firebox.[56] The Scope soldering iron uses a graphite tip as its heating element.

Expanded graphite

Expanded graphite is made by immersing natural flake graphite in a bath of chromic acid, then concentrated sulfuric acid, which forces the crystal lattice planes apart, thus expanding the graphite. The expanded graphite can be used to make graphite foil or used directly as a "hot top" compound to insulate molten metal in a ladle or red-hot steel ingots and decrease heat loss, or as firestops fitted around a fire door or in sheet metal collars surrounding plastic pipe (during a fire, the graphite expands and chars to resist fire penetration and spread), or to make high-performance gasket material for high-temperature use. After being made into graphite foil, the foil is machined and assembled into the bipolar plates in fuel cells. The foil is made into heat sinks for laptop computers which keeps them cool while saving weight, and is made into a foil laminate that can be used in valve packings or made into gaskets. Old-style packings are now a minor member of this grouping: fine flake graphite in oils or greases for uses requiring heat resistance. A GAN estimate of current US natural graphite consumption in this end-use is 7,500 tonnes.[46]

الگرافيت المقحم

Graphite forms intercalation compounds with some metals and small molecules. In these compounds, the host molecule or atom gets "sandwiched" between the graphite layers, resulting in a type of compound with variable stoichiometry. A prominent example of an intercalation compound is potassium graphite, denoted by the formula KC8. Some graphite intercalation compounds are superconductors. The highest transition temperature (by June 2009) Tc = 11.5 K is achieved in CaC6, and it further increases under applied pressure (15.1 K at 8 GPa).[57] Graphite's ability to intercalate lithium ions without significant damage from swelling is what makes it the dominant anode material in lithium-ion batteries.

تاريخ الجرافيت الاصطناعي

اختراع عملية لانتاج الجرافيت الاصطناعي

In 1893, Charles Street of Le Carbone discovered a process for making artificial graphite. In the mid-1890s, Edward Goodrich Acheson (1856–1931) accidentally invented another way to produce synthetic graphite after synthesizing carborundum (also called silicon carbide). He discovered that overheating carborundum, as opposed to pure carbon, produced almost pure graphite. While studying the effects of high temperature on carborundum, he had found that silicon vaporizes at about 4،150 °C (7،500 °F), leaving the carbon behind in graphitic carbon. This graphite became valuable as a lubricant.[7]

Acheson's technique for producing silicon carbide and graphite is named the Acheson process. In 1896, Acheson received a patent for his method of synthesizing graphite,[58] and in 1897 started commercial production.[7] The Acheson Graphite Co. was formed in 1899.

Synthetic graphite can also be prepared from polyimide and then commercialized.[59][60]

Hydrogen production via pyrolysis of methane and graphite

قالب:Advertisement Methane pyrolysis refers to the thermal decomposition of methane. Methane pyrolysis splits the natural gas directly into hydrogen and solid carbon. The solid carbon can be used in steel or aluminium production. If the energy comes from renewables, the hydrogen can be produced on an industrial scale without emissions.

Several companies and universities have studied this process. An Australian company has developed a process – "The HAZER® Process" – which uses iron ore to catalyse the conversion of natural gas and other feedstocks into hydrogen and high-quality graphite.[61] at a ratio of one 1 t (1.1 short ton) of hydrogen to 3 t (3.3 short ton) of graphite.

Importantly, there is less environmental damage, as the HAZER® Process does not need to excavate mass areas of land like natural graphite extraction and does not require the use of harsh chemicals like petroleum coke used to create current synthetic graphite."[61]

NOVONIX

Novonix is an Australian Listed company which has developed proprietary technology that includes unique continuous graphitization systems.

It has planned, by 2030, a yearly North American production capacity of 150،000 t (170،000 short ton).[62]

Other companies using Methane Pyrolysis

Monolith

The American company, Monolith, is also working an emission-free methane pyrolysis unit. Instead of graphite, this process results in carbon black.[63]

Monolith's process is another way of producing hydrogen without any emissions of carbon dioxide (CO2), joining those that rely on water electrolysers and carbon capture. It produces hydrogen at a ratio of 1 t (1.1 short ton) for every 3 t (3.3 short ton) tonnes of carbon black."[64]

BASFقالب:Expand acronym is also working on methane pyrolysis as a greener way of producing hydrogen. On a lab scale, it has been successful.[65]

Environmental, social, and governance (ESG) difference from natural and synthetic graphite

Making battery-grade graphite from natural graphite involves intensive purification and shaping into spherical form, which relies on large quantities of hydrofluoric acid (HF). This downstream process, currently only done in China, has much deeper ESG concerns.

To make battery-grade graphite from the natural involves intensive purification and shaping into spherical form. This process relies on large quantities of hydrofluoric acid. This downstream process, currentlyقالب:As of? only done in China, has much deeper ESG concerns. China has been introducing strict regulations since the mid-2010s. However, frequent inspections[ممن؟] have resulted in ongoing rounds of temporary capacity closures – and some permanent. This has led to supply shortages and price rises. Graphite now appears on many countries’ official lists of critical materials due to concerns over both ESG and China's control over supply volumes and prices.

Several mine developers outside China are looking to create a new supply chain, with plants being considered in locations around the world. Most are looking to use alternative, low- or zero-HF methodologies, such as acid-alkali or thermal-only. However, the former uses a strong set of environmentally challenging reagents, while the latter entails high energy consumption and production costs. Some companies are exploring other proprietary methods, none of which have yetقالب:As of? been proven at scale.[66]

The extraction, transport, and processing of natural graphite involves the following externalities:

- destruction of natural habitat and loss of biodiversity;

- contamination of soil, groundwater, surface water, and air by chemicals, oil, fuel, and emissions from mining processes;

- erosion, sinkholes, and alteration of soil profiles due to land-use change;

- acid mine drainage and runoff from mining sites; and,

- an increase in noise level, dust, and carbon emissions, which contribute to climate change[67]

Synthetic graphite production impacts vary significantly by company. The HAZER® Process is carbon negative[68] while Novonix process uses significant amounts of electricity. The latter company says its energy input is 57% carbon-free (15% renewable)قالب:As of? with a target to be net-zero by 2050.[69]

Neither HAZER® nor Novonix use chemical purification to eliminate the risk of chemical leaks, spills and exposures.

البحث العلمي

Highly oriented pyrolytic graphite (HOPG) is the highest-quality synthetic form of graphite. It is used in scientific research, in particular, as a length standard for the calibration of scanning probe microscopes.[70][71]

Electrodes

Graphite electrodes carry the electricity that melts scrap iron and steel, and sometimes direct-reduced iron (DRI), in electric arc furnaces, which are the vast majority of steel furnaces. They are made from petroleum coke after it is mixed with coal tar pitch. They are extruded and shaped, then baked to carbonize the binder (pitch). This is finally graphitized by heating it to temperatures approaching 3،000 °C (5،430 °F), at which the carbon atoms arrange into graphite. They can vary in size up to 3.5 m (11 ft) long and 75 cm (30 in) in diameter. An increasing proportionقالب:As of? of global steel is made using electric arc furnaces, and the electric arc furnace itself is becoming more efficient, making more steel per tonne of electrode. An estimate based on USGS data indicates that graphite electrode consumption was 197،000 t (217،000 short ton) in 2005.[46]

Electrolytic aluminium smelting also uses graphitic carbon electrodes. On a much smaller scale, synthetic graphite electrodes are used in electrical discharge machining (EDM), commonly to make injection molds for plastics.[72]

Powder and scrap

The powder is made by heating powdered petroleum coke above the temperature of graphitization, sometimes with minor modifications. The graphite scrap comes from pieces of unusable electrode material (in the manufacturing stage or after use) and lathe turnings, usually after crushing and sizing. Most synthetic graphite powder goes to carbon raising in steel (competing with natural graphite), with some used in batteries and brake linings. According to the United States Geographical Survey, US synthetic graphite powder and scrap production were 95،000 t (93،000 long ton; 105،000 short ton) in 2001 (latest data).[46]

Neutron moderator

Special grades of synthetic graphite, such as Gilsocarbon,[73][74] also find use as a matrix and neutron moderator within nuclear reactors. Its low neutron cross-section also recommends it for use in proposed fusion reactors. Care must be taken that reactor-grade graphite is free of neutron absorbing materials such as boron, widely used as the seed electrode in commercial graphite deposition systems – this caused the failure of the Germans' World War II graphite-based nuclear reactors. Since they could not isolate the difficulty they were forced to use far more expensive heavy water moderators. Graphite used for nuclear reactors is often referred to as nuclear graphite. Herbert G. McPherson, a Berkeley trained physicist at National Carbon, a division of Union Carbide, was key in confirming a conjecture of Leo Szilard that boron impurities even in "pure" graphite were responsible for a neutron absorption cross-section in graphite that compromised U-235 chain reactions. McPherson was aware of the presence of impurities in graphite because, with the use of Technicolor in cinematography, the spectra of graphite electrode arcs used in movie projectors required impurities to enhance emission of light in the red region to display warmer skin tones on the screen. Thus, had it not been for color movies, chances are that the first sustained natural U chain reaction would have required a heavy water moderated reactor.[75]

استخدامات أخرى

Graphite (carbon) fiber and carbon nanotubes are also used in carbon fiber-reinforced plastics, and in heat-resistant composites such as reinforced carbon-carbon (RCC). Commercial structures made from carbon fiber graphite composites include fishing rods, golf club shafts, bicycle frames, sports car body panels, the fuselage of the Boeing 787 Dreamliner and pool cue sticks and have been successfully employed in reinforced concrete. The mechanical properties of carbon fiber graphite-reinforced plastic composites and grey cast iron are strongly influenced by the role of graphite in these materials. In this context, the term "(100%) graphite" is often loosely used to refer to a pure mixture of carbon reinforcement and resin, while the term "composite" is used for composite materials with additional ingredients.[76]

Modern smokeless powder is coated in graphite to prevent the buildup of static charge.

Graphite has been used in at least three radar absorbent materials. It was mixed with rubber in Sumpf and Schornsteinfeger, which were used on U-boat snorkels to reduce their radar cross section. It was also used in tiles on early F-117 Nighthawk stealth strike fighters.

Graphite composites are used as absorber for high-energy particles, for example in the Large Hadron Collider beam dump.[77]

Graphite rods when filed into shape are used as a tool in glassworking to manipulate hot molten glass.[78]

تعدين و beneficiation وتشغيل الجرافيت

Graphite is mined by both open pit and underground methods. Graphite usually needs beneficiation. This may be carried out by hand-picking the pieces of gangue (rock) and hand-screening the product or by crushing the rock and floating out the graphite. Beneficiation by flotation encounters the difficulty that graphite is very soft and "marks" (coats) the particles of gangue. This makes the "marked" gangue particles float off with the graphite, yielding impure concentrate. There are two ways of obtaining a commercial concentrate or product: repeated regrinding and floating (up to seven times) to purify the concentrate, or by acid leaching (dissolving) the gangue with hydrofluoric acid (for a silicate gangue) or hydrochloric acid (for a carbonate gangue).

In milling, the incoming graphite products and concentrates can be ground before being classified (sized or screened), with the coarser flake size fractions (below 8 mesh, 8–20 mesh, 20–50 mesh) carefully preserved, and then the carbon contents are determined. Some standard blends can be prepared from the different fractions, each with a certain flake size distribution and carbon content. Custom blends can also be made for individual customers who want a certain flake size distribution and carbon content. If flake size is unimportant, the concentrate can be ground more freely. Typical end products include a fine powder for use as a slurry in oil drilling and coatings for foundry molds, carbon raiser in the steel industry (Synthetic graphite powder and powdered petroleum coke can also be used as carbon raiser). Environmental impacts from graphite mills consist of air pollution including fine particulate exposure of workers and also soil contamination from powder spillages leading to heavy metal contamination of soil.

According to the United States Geological Survey (USGS), world production of natural graphite in 2016 was 1,200,000 tonnes, of which the following major exporters are: China (780,000 t), India (170,000 t), Brazil (80,000 t), Turkey (32,000 t) and North Korea (6,000 t).[79] Graphite is not currently mined in the United States, but there are many historical mine sites including ones in Alabama, Montana, and in the Adirondacks of NY.[80] Westwater Resources is in the development stages of creating a pilot plant for their Coosa Graphite Mine near Sylacauga, Alabama.[81] U.S. production of synthetic graphite in 2010 was 134,000 t valued at $1.07 billion.[46]

السلامة المهنية

Potential health effects include:

- Inhalation: No inhalation hazard in manufactured and shipped state. Dust and fumes generated from the material can enter the body by inhalation. High concentrations of dust and fumes may irritate the throat and respiratory system and cause coughing. Frequent inhalation of fume/dust over a long period of time increases the risk of developing lung diseases. Prolonged and repeated overexposure to dust can lead to pneumoconiosis. Pre-existing pulmonary disorders, such as emphysema, may possibly be aggravated by prolonged exposure to high concentrations of graphite dusts.

- Eye contact: Dust in the eyes will cause irritation. Exposed may experience eye tearing, redness, and discomfort.

- Skin contact: Under normal conditions of intended use, this material does not pose a risk to health. Dust may irritate skin.

- Ingestion: Not relevant, due to the form of the product in its manufactured and shipped state. However, ingestion of dusts generated during working operations may cause nausea and vomiting.

- Potential physical / chemical effects: Bulk material is non-combustible. The material may form dust and can accumulate electrostatic charges, which may cause an electrical spark (ignition source). High dust levels may create potential for explosion.

الولايات المتحدة

The Occupational Safety and Health Administration (OSHA) has set the legal limit (permissible exposure limit) for graphite exposure in the workplace as a time weighted average (TWA) of 15 million particles per cubic foot (1.5 mg/m3) over an 8-hour workday. The National Institute for Occupational Safety and Health (NIOSH) has set a recommended exposure limit (REL) of TWA 2.5 mg/m3 respirable dust over an 8-hour workday. At levels of 1250 mg/m3, graphite is immediately dangerous to life and health.[82]

تدوير الجرافيت

The most common way of recycling graphite occurs when synthetic graphite electrodes are either manufactured and pieces are cut off or lathe turnings are discarded for reuse, or the electrode (or other materials) are used all the way down to the electrode holder. A new electrode replaces the old one, but a sizeable piece of the old electrode remains. This is crushed and sized, and the resulting graphite powder is mostly used to raise the carbon content of molten steel.

Graphite-containing refractories are sometimes also recycled, but often are not due to their low graphite content: the largest-volume items, such as carbon-magnesite bricks that contain only 15–25% graphite, usually contain too little graphite to be worthwhile to recycle. However, some recycled carbon–magnesite brick is used as the basis for furnace-repair materials, and also crushed carbon–magnesite brick is used in slag conditioners.

While crucibles have a high graphite content, the volume of crucibles used and then recycled is very small.

A high-quality flake graphite product that closely resembles natural flake graphite can be made from steelmaking kish. Kish is a large-volume near-molten waste skimmed from the molten iron feed to a basic oxygen furnace and consists of a mix of graphite (precipitated out of the supersaturated iron), lime-rich slag, and some iron. The iron is recycled on-site, leaving a mixture of graphite and slag. The best recovery process uses hydraulic classification (which utilizes a flow of water to separate minerals by specific gravity: graphite is light and settles nearly last) to get a 70% graphite rough concentrate. Leaching this concentrate with hydrochloric acid gives a 95% graphite product with a flake size ranging from 10 mesh (2 mm) down.

وسائط

-

رسوم متحركة للگرافيت (file info) — شاهد في المتصفح

- ستريوگرام دوار للگرافيت. (2.79 MB, animated GIF format).

- هل هناك مشكلة في مشاهدة الفيديو؟ انظر media help.

انظر أيضاً

المصادر

- ^ "Graphite at Mindat".

- ^ "Webmineral".

- ^ أ ب ت Handbook of Mineralogy

- ^ "Thermal properties of graphite — thermal conductivity". CFC Carbon Ltd. Retrieved 17 March 2023.

- ^ Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. ISBN 978-0-08-037941-8.

- ^ Sutphin, David M.; James D. Bliss (August 1990). "Disseminated flake graphite and amorphous graphite deposit types; an analysis using grade and tonnage models". CIM Bulletin. 83 (940): 85–89.

- ^ أ ب ت ث ج ح graphite. Encyclopædia Britannica Online.

- ^ IUPAC, Compendium of Chemical Terminology, 2nd ed. (the "Gold Book") (1997). Online corrected version: (2006–) "highly oriented pyrolytic graphite".

- ^ https://www.sciencedirect.com/topics/chemical-engineering/artificial-graphite.

{{cite web}}: Missing or empty|title=(help) - ^ "Graphite". Minerals Database. Minerals Education Coalition. 2018. Retrieved 9 December 2018.

- ^ Lugaro, Maria (2005). Stardust From Meteorites: An Introduction To Presolar Grains. World Scientific. pp. 14, 154–157. ISBN 9789814481373.

- ^ Hazen, R. M.; Downs, R. T.; Kah, L.; Sverjensky, D. (13 February 2013). "Carbon Mineral Evolution". Reviews in Mineralogy and Geochemistry. 75 (1): 79–107. Bibcode:2013RvMG...75...79H. doi:10.2138/rmg.2013.75.4.

- ^ McCoy, T. J. (22 February 2010). "Mineralogical Evolution of Meteorites". Elements. 6 (1): 19–23. doi:10.2113/gselements.6.1.19.

- ^ Delhaes, Pierre (2000). "Polymorphism of carbon". In Delhaes, Pierre (ed.). Graphite and precursors. Gordon & Breach. pp. 1–24. ISBN 9789056992286.

- ^ Pierson, Hugh O. (2012). Handbook of carbon, graphite, diamond, and fullerenes : properties, processing, and applications. Noyes Publications. pp. 40–41. ISBN 9780815517399.

- ^ Delhaes, P. (2001). Graphite and Precursors. CRC Press. ISBN 978-90-5699-228-6.

- ^ Chung, D. D. L. (2002). "Review Graphite". Journal of Materials Science. 37 (8): 1475–1489. doi:10.1023/A:1014915307738. S2CID 189839788.

- ^ Pierson, Hugh O. (1993). Handbook of carbon, graphite, diamond, and fullerenes : properties, processing, and applications. Park Ridge, N.J.: Noyes Publications. ISBN 0-8155-1739-4. OCLC 49708274.

- ^ Latychevskaia, Tataiana; Son, Seok-Kyun; Yang, Yaping; Chancellor, Dale; Brown, Michael; Ozdemir, Servet; Madan, Ivan; Berruto, Gabriele; Carbone, Fabrizio; Mishchenko, Artem; Novoselov, Kostya (2019-08-17). "Stacking transition in rhombohedral graphite". Frontiers of Physics. 14 (1). 13608. arXiv:1908.06284. Bibcode:2019FrPhy..1413608L. doi:10.1007/s11467-018-0867-y. S2CID 125322808.

- ^ IUPAC, Compendium of Chemical Terminology, 2nd ed. (the "Gold Book") (1997). Online corrected version: (2006–) "Rhombohedral graphite".

- ^ أ ب Bundy, P.; Bassett, W. A.; Weathers, M. S.; Hemley, R. J.; Mao, H. K.; Goncharov, A. F. (1996). "The pressure-temperature phase and transformation diagram for carbon; updated through 1994". Carbon. 34 (2): 141–153. doi:10.1016/0008-6223(96)00170-4.

- ^ Wang, C. X.; Yang, G. W. (2012). "Thermodynamic and kinetic approaches of diamond and related nanomaterials formed by laser ablation in liquid". In Yang, Guowei (ed.). Laser ablation in liquids : principles and applications in the preparation of nanomaterials. Pan Stanford Pub. pp. 164–165. ISBN 9789814241526.

- ^ Rock, Peter A. (1983). Chemical Thermodynamics. University Science Books. pp. 257–260. ISBN 9781891389320.

- ^ Hanaor, D.; Michelazzi, M.; Leonelli, C.; Sorrell, C.C. (2011). "The effects of firing conditions on the properties of electrophoretically deposited titanium dioxide films on graphite substrates". Journal of the European Ceramic Society. 31 (15): 2877–2885. arXiv:1303.2757. doi:10.1016/j.jeurceramsoc.2011.07.007. S2CID 93406448.

- ^ Deprez, N.; McLachlan, D. S. (1988). "The analysis of the electrical conductivity of graphite conductivity of graphite powders during compaction". Journal of Physics D: Applied Physics. 21 (1): 101–107. Bibcode:1988JPhD...21..101D. doi:10.1088/0022-3727/21/1/015. S2CID 250886376.

- ^ Lavrakas, Vasilis (1957). "Textbook errors: Guest column. XII: The lubricating properties of graphite". Journal of Chemical Education. 34 (5): 240. Bibcode:1957JChEd..34..240L. doi:10.1021/ed034p240.

- ^ Watanabe, N.; Hayakawa, H.; Yoshimoto, O.; Tojo, T. (2000). "The lubricating properties of graphite fluoride composites under both atmosphere and high vacuum condition". FY2000 Ground – Based Research Announcement for Space Utilization Research Report.

- ^ Yen, Bing; Schwickert, Birgit (2004). Origin of low-friction behavior in graphite investigated by surface x-ray diffraction, SLAC-PUB-10429. Archived from the original. You must specify the date the archive was made using the

|archivedate=parameter. http://www.slac.stanford.edu/cgi-wrap/getdoc/slac-pub-10429.pdf. Retrieved on March 15, 2013. - ^ Galvanic Corrosion Archived 2009-03-10 at the Wayback Machine. keytometals.com

- ^ "ASM Tech Notes – TN7-0506 – Galvanic Corrosion" (PDF). Atlas Specialty Metals. Archived from the original (PDF) on 2009-02-27.

- ^ Jones, Rick (USAF-Retired) Better Lubricants than Graphite. graflex.org

- ^ "Weapons Lubricant in the Desert". September 16, 2005. Archived from the original on 2007-10-15. Retrieved 2009-06-06.

- ^ "Good Engineering Practice/Corrosion". Lotus Seven Club. 9 April 2003. Archived from the original on 16 September 2009.

- ^ Marsh, Harry; Reinoso, Francisco Rodríguez (2007). Activated carbon (1st ed.). Elsevier. pp. 497–498. ISBN 9780080455969.

- ^ Boardman, John. "The Neolithic-Eneolithic Period" (PDF). The Cambridge ancient history, Volume 3, Part 1. pp. 31–32. ISBN 978-0521224963. Archived from the original (PDF) on 25 February 2013.

- ^ Norgate, Martin; Norgate, Jean (2008). "Old Cumbria Gazetteer, black lead mine, Seathwaite". Geography Department, Portsmouth University. Retrieved 2008-05-19.

- ^ Wainwright, Alfred (2005). A Pictorial Guide to the Lakeland Fells, Western Fells. London: Frances Lincoln. ISBN 978-0-7112-2460-5.

- ^ The Statutes at Large: From the ... Year of the Reign of ... to the ... Year of the Reign of . 1764. p. 415.

- ^ "History". Dixon Ticonderoga Company. Archived from the original on 7 April 2018.

- ^ أ ب Nguyen, Ahn (2003). Colloidal Science of Flotation. CRC Press. p. 11. ISBN 978-0824747824.

- ^ Cirkel, Fritz (1907). Graphite its Properties, Occurrence, Refining and Uses. Ottawa: Canadian Department of Mines. p. passim. Retrieved 6 April 2018.

- ^ Electro-Plating on Non-Metallic Substances. Spons' Workshop Receipts Vol. II: Dyeing to Japanning. Spon. 1921. p. 132.

- ^ Evans, John W. (1908). "V.— the Meanings and Synonyms of Plumbago". Transactions of the Philological Society. 26 (2): 133–179. doi:10.1111/j.1467-968X.1908.tb00513.x.

- ^ Widenmann, Johann Friedrich Wilhelm (1794). Handbuch des oryktognostischen Theils der Mineralogie: Mit einer Farbentabelle und einer Kupfertafel. Crusius. p. 653.

- ^ Scheele, C. W. K. (1779). "Versuche mit Wasserbley; Molybdaena". Svenska Vetensk. Academ. Handlingar. 40: 238.

- ^ أ ب ت ث ج ح خ د "Graphite Statistics and Information". USGS. Retrieved 2009-09-09.

- ^ وليد خليفة. "الحراريات المتالورجية: الأنواع والتركيبات الكيميائية (5) - حراريات الكربون". نول. Retrieved 2012-03-27.

- ^ "Graphite/Metal Alloy Extends Material Life in High-Temperature Processes". Foundry Management & Technology. 2004-06-04. Retrieved 2019-06-20.

- ^ قالب:OEtymD

- ^ Ritter, Steve (October 15, 2001). "Pencils & Pencil Lead". American Chemical Society.

- ^ "The History of the Pencil". University of Illinois at Urbana–Champaign. Archived from the original on 2015-03-17. Retrieved 2013-02-15.

- ^ "Electric Graphite Growing Demand From Electric Vehicles & Mobile Electronics" (PDF). galaxycapitalcorp.com. July 20, 2011. Archived from the original (PDF) on October 4, 2013. Retrieved February 15, 2013.

- ^ Not known (January 29, 2018). "ART TECHNIQUE-GRAPHITE AS A MEDIUM". Sybaris.

- ^ "Top 5 Speed Tips for Your Pinewood Derby Car". S&W Crafts Mfg. Retrieved July 28, 2022.

- ^ "Module 6: Media for 2-D Art" (PDF). Saylor.org. Archived (PDF) from the original on 2012-08-09. Retrieved 2 April 2012.

- ^ True color/appearance of the "Graphite, or Smokebox colors. List.nwhs.org. Retrieved on 2013-04-15.

- ^ Emery, Nicolas; Hérold, Claire; Marêché, Jean-François; Lagrange, Philippe (2008). "Synthesis and superconducting properties of CaC6". Sci. Technol. Adv. Mater. 9 (4): 044102. Bibcode:2008STAdM...9d4102E. doi:10.1088/1468-6996/9/4/044102. PMC 5099629. PMID 27878015.

- ^ Acheson, E. G. "Manufacture of Graphite", U.S. Patent 568٬323, issued September 29, 1896.

- ^ Kato, Tomofumi; Yamada, Yasuhiro; Nishikawa, Yasushi; Ishikawa, Hiroki; Sato, Satoshi (2021-06-30). "Carbonization mechanisms of polyimide: Methodology to analyze carbon materials with nitrogen, oxygen, pentagons, and heptagons". Carbon. 178: 58–80. doi:10.1016/j.carbon.2021.02.090. ISSN 0008-6223. S2CID 233539984.

- ^ Kato, Tomofumi; Yamada, Yasuhiro; Nishikawa, Yasushi; Otomo, Toshiya; Sato, Hayato; Sato, Satoshi (2021-07-12). "Origins of peaks of graphitic and pyrrolic nitrogen in N1s X-ray photoelectron spectra of carbon materials: quaternary nitrogen, tertiary amine, or secondary amine?". Journal of Materials Science. 56 (28): 15798–15811. Bibcode:2021JMatS..5615798K. doi:10.1007/s10853-021-06283-5. ISSN 1573-4803. S2CID 235793266.

- ^ أ ب "The Hazer Process". Hazer Group.

- ^ https://ir.novonixgroup.com/static-files/0a3d07fd-f2a0-4d92-9593-eba24e53446e.

{{cite web}}: Missing or empty|title=(help) - ^ https://monolith-corp.com/.

{{cite web}}: Missing or empty|title=(help) - ^ https://www.icis.com/explore/resources/news/2022/01/05/10722011/insight-us-monolith-to-expand-world-s-largest-methane-pyrolysis-plant/.

{{cite web}}: Missing or empty|title=(help) - ^ https://www.thechemicalengineer.com/news/basf-announces-four-research-projects-for-reducing-co2-emissions/.

{{cite web}}: Missing or empty|title=(help) - ^ "Energy transition metals: the ESG dilemma".

- ^ "What Is The Environmental Impact Of The Mining Industry?".

- ^ "World-first project to turn biogas from sewage into hydrogen and graphite".

- ^ "Novonix".

- ^ R. V. Lapshin (1998). "Automatic lateral calibration of tunneling microscope scanners" (PDF). Review of Scientific Instruments. 69 (9): 3268–3276. Bibcode:1998RScI...69.3268L. doi:10.1063/1.1149091. ISSN 0034-6748. Archived (PDF) from the original on 2013-10-06.

- ^ R. V. Lapshin (2019). "Drift-insensitive distributed calibration of probe microscope scanner in nanometer range: Real mode". Applied Surface Science. 470: 1122–1129. arXiv:1501.06679. Bibcode:2019ApSS..470.1122L. doi:10.1016/j.apsusc.2018.10.149. ISSN 0169-4332. S2CID 119275633.

- ^ Pierson, Hugh O. (1993). Handbook of Carbon, Graphite, Diamonds and Fullerenes: Properties, Processing and Applications. Noyes Publications. ISBN 0-8155-1339-9. OL 8048799M.

- ^ Arregui-Mena, J. D.; Bodel, W.; et al. (2016). "Spatial variability in the mechanical properties of Gilsocarbon". Carbon. 110: 497–517. doi:10.1016/j.carbon.2016.09.051.

- ^ Arregui Mena, J.D.; et al. (2018). "Characterisation of the spatial variability of material properties of Gilsocarbon and NBG-18 using random fields". Journal of Nuclear Materials. 511: 91–108. Bibcode:2018JNuM..511...91A. doi:10.1016/j.jnucmat.2018.09.008. S2CID 105291655.

- ^ Weinberg, Alvin M. (1994). The First Nuclear Era. New York, N.Y.: American Institute of Physics. Figure 11. ISBN 978-1563963582.

- ^ Cooper, Jeff. What is the best material for a tennis racquet? Archived 2011-07-07 at the Wayback Machine. tennis.about.com

- ^ Yurkewicz, Katie. "Protecting the LHC from itself" (PDF). Symmetry Magazine. Archived (PDF) from the original on 2015-09-10.

- ^ Olmec Advanced Materials (2019). "How graphite is used in the glass and fibreglass industries". Retrieved 19 January 2019.

- ^ "Mineral Commodity Summaries 2020" (PDF). National Minerals Information Center. USGS. Archived (PDF) from the original on 2017-02-09.

- ^ "Wonder 5: Graphite Mines – Boom Town". 24 March 2015.

- ^ Jeremy Law (2018-05-16). "Westwater Resources acquires Alabama Graphite" (in الإنجليزية الأمريكية). Retrieved 2020-02-22.

- ^ "CDC – NIOSH Pocket Guide to Chemical Hazards – Graphite (natural)". www.cdc.gov. Retrieved 2015-11-03.

- C.Michael Hogan, Marc Papineau et al., Phase I Environmental Site Assessment, Asbury Graphite Mill, 2426-2500 Kirkham Street, Oakland, California, Earth Metrics report 10292.001, December 18, 1989

- Klein, Cornelis and Cornelius S. Hurlbut, Jr. (1985) Manual of Mineralogy: after Dana 20th ed. ISBN 0-471-80580-7

- Taylor, Harold A., "Graphite", Financial Times Executive Commodity Reports (London: Mining Journal Books ltd.) 2000 ISBN 1-84083-332-7

- Taylor, Harold A., "Graphite", Industrial Minerals and Rocks, 7th ed. (Littleton, CO AIME-Society of Mining Engineers) 2005 ISBN 0-87335-233-5

قراءات للإستزادة

- C.Michael Hogan, Marc Papineau et al. (December 18, 1989). 'Phase I Environmental Site Assessment, Asbury Graphite Mill, 2426-2500 Kirkham Street, Oakland, California, Earth Metrics report 10292.001'.

- Klein, Cornelis and Cornelius S. Hurlbut, Jr. (1985). Manual of Mineralogy: after Dana (20th ed.). ISBN 0-471-80580-7.

{{cite book}}: CS1 maint: multiple names: authors list (link) - Taylor, Harold A. (2000). Graphite. Financial Times Executive Commodity Reports. London: Mining Journal Books ltd. ISBN 1-84083-332-7.

- Taylor, Harold A. (2005). Graphite. Industrial Minerals and Rocks (7th ed.). Littleton, CO: AIME-Society of Mining Engineers. ISBN 0-87335-233-5.

وصلات خارجية

- The Graphite Page

- Mineral galleries

- Webmineral

- Mindat w/ locations

- giant covalent structures

- USGS 2005 Minerals Yearbook: Graphite

- USGS 2006 Minerals Yearbook: Graphite

- Graphite Statistics and Information - United States Geological Survey minerals information for graphite

- Link to 'Graphite - a New Twist' - Video lecture by Prof. Malcolm Heggie, University of Sussex.

- CS1 errors: missing title

- CS1 errors: bare URL

- CS1 الإنجليزية الأمريكية-language sources (en-us)

- Short description matches Wikidata

- Pages using Infobox mineral with unknown parameters

- Articles with hatnote templates targeting a nonexistent page

- Articles with specifically marked weasel-worded phrases from September 2023

- Pages using div col with unknown parameters

- جرافيت

- Native element minerals

- مزلقات

- مواد فنية

- صيغ الكربون

- مواد حرارية

- موصلات كهربائية

- تدوير

- مواد قابلة للتدوير

- مزلقات غير نفطية

- مزلقات جافة

- معادن سداسية الأضلاع

- Minerals in space group 186

- Minerals in space group 194

- Shades of black

- كلمات وعبارات يونانية

- معادن صناعية